An ambitious vision for the Port of Montreal: New container terminal at the Port of Contrecœur

- Client

- Montreal Port Authority

- Sector

- Marine Works

- Delivery mode

- Design-Build

- Location

- Contrecoeur, QC, CA

- Year built

- 2029

The Montreal Port Authority (MPA) is considering the creation of a new container terminal at the Contrecœur site to meet growing maritime trade demand. This project will be carried out in collaborative mode.

The Constructeurs Terminal de Contrecoeur Grand Projet (CTCGP) consortium, composed of Pomerleau (60% representative) and Aecon, and MPA worked on the co-development phase which extended until September 2025. The Progressive Design approach allowed the project design to evolve in parallel with budget estimates and planning. Within this framework, in November 2023, the APM awarded the CTCGP consortium, the contract for the design and construction of the waterworks, including the quay wall and the dredging pocket.

The new phase, construction, is scheduled to begin in the fall of 2025. It will bring to fruition the work defined and planned during the co-development phase, with a view to providing the Port of Montreal with strategic and sustainable infrastructure.

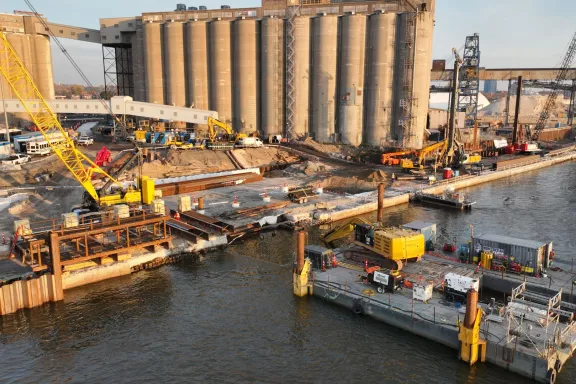

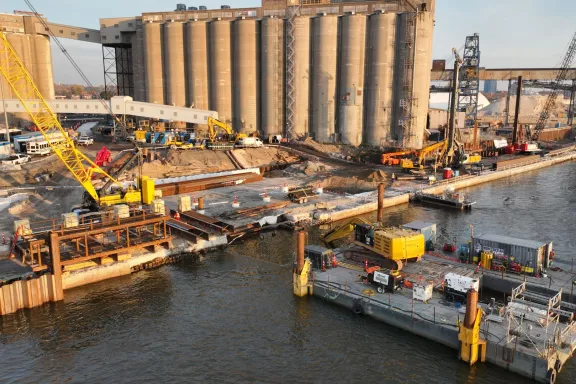

Building in water: a technical feat

The heart of the project is the construction of robust and sustainable marine infrastructure. Two berths, totaling 675 meters, will be built to accommodate large-capacity vessels, particularly in terms of containers. Return walls to the east and west will ensure the stability of the structure, while riprap will protect the structures from erosion.

Behind the quay wall, a technical embankment and drainage systems will be installed to support the structure and manage runoff. Finally, a dredging pocket, an area dug into the seabed to ensure sufficient draft for ships, will be excavated to guarantee sufficient draft, with rigorous management of the extracted material.

Challenges commensurate with the scale of the project

Building in freezing conditions

The environmental window for dredging runs from October 15 to March 31, which means that work must be carried out in difficult winter conditions. Environmental requirements for suspended solids are strict, necessitating planned work stoppages.

Constraints and logistics

The dredging partner, one of the largest in the world, imposes contractual rigor that requires careful management. Added to this is the management of construction site water, which is subject to high quality standards before being discharged into the river. More than 500,000 m³ of backfill material will have to be transported and placed in a single season, a major logistical challenge.

Being a committed partner

Faced with these challenges, Pomerleau and Aecon are supporting the client with concrete, intelligent solutions. One major innovation is to store the dredged material on site in a large-capacity basin, thereby reducing environmental impacts and logistics costs.

A dedicated access road for heavy transport has been created to avoid Road 132, limiting disruption for local residents. The work schedule has been optimized to reduce noise pollution, particularly at night and on weekends. Finally, a collaborative approach with designers allows technical requirements to be reviewed in order to stay within budget without compromising quality.

A construction site under environmental monitoring

The project site is located in the habitat of the copperhead, an endangered fish species. Therefore, the construction site must comply with certain regulatory and environmental obligations. Fourteen buoys equipped with probes will be deployed to continuously measure water quality, allowing for adaptive management of the work.

Before each season of work in the water, sensitive mollusks known as freshwater mussels will be relocated. On land, the presence of tree frogs imposes restrictions to protect their habitat. Finally, the management of common reed (Phragmites), an invasive plant, will require decontamination of the land and specific ecological measures.

Innovation at the service of precision

This project stands out for its integration of cutting-edge technologies. The real-time water quality monitoring system, based on buoys equipped with probes, enables rapid response and optimal protection of ecosystems.

All earthwork equipment is geolocated, ensuring efficient coordination and increased safety. The mechanical dredger used is equipped with a millimeter positioning system and intelligent virtual barriers, guaranteeing exceptional precision and control of environmental impacts.

High-resolution multibeam bathymetry allows the seabed to be mapped with great precision, facilitating the monitoring of the underwater relief. Finally, the project relies on the use of BIM (Building Information Modeling), a 3D digital modeling technique that ensures perfect consistency between design and execution.

Human and technical resources

The project will mobilize approximately 80 management personnel and 200 workers. Pomerleau's Civil Infra teams will be called upon, particularly for urban earthworks and deep foundations, two key areas of expertise for the success of this complex project.

Pomerleau is proud to contribute to this strategic project for the development of the Port of Montreal, leveraging its technical expertise, environmental commitment and capacity for innovation to build a sustainable future.